Remotoring the Mantua General

Part 1 - mounting the motor

Background

One of the better locomotive

options for your HO scale Civil War model railroad is a

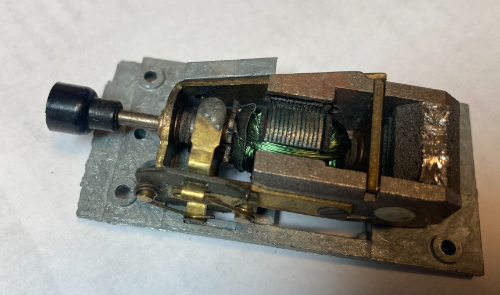

Mantua/Tyco General. These locomotives come with open frame motors

that are not the best performers. I have found a 12 volt

PC-130 DC motor is a very usable replacement. I use DCC on my

layout and I plan on putting sound under my layout rather in the

engines/tenders. I drive the motor with a Digitrax 1 AMP Z scale

decoder (DZ123). My remotored locomotives run smoother than with

the original motor though top speed may be a bit lower. This is

not a concern to me because my layout largely consists of a yard in

which locomotives would be operating at reduced speeds.

This remotoring is inspired by the remotoring part of Al Mueller's Mantua General Rebuild document, but there are several differences in execution, which I believe make this version a bit easier to implement.

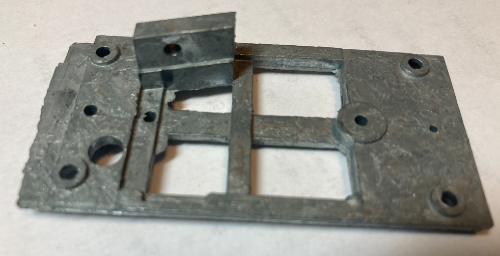

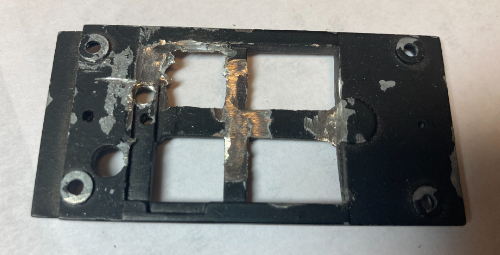

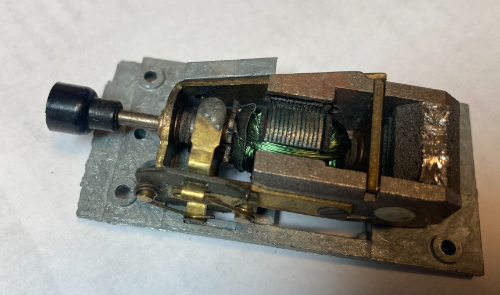

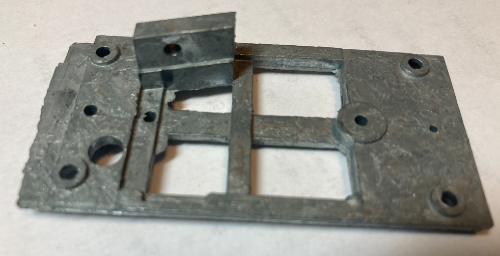

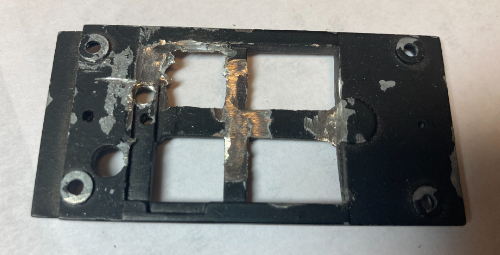

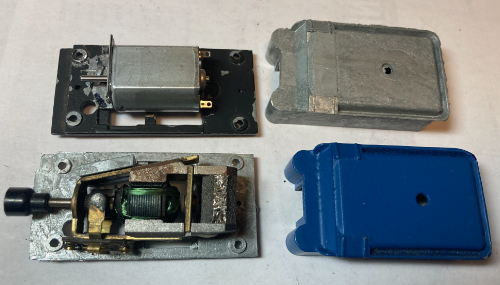

The tender frame contains a mount for the original open frame motor.

In order to fit the new can motor properly so the drive shaft is located

at the same place as the original open frame motor, the old mount must

be removed and the cross brace must be milled down. I use dremel

cut off disks and various small drills and files to remove parts of the

casting.

Note that the modified frame has the mounting bracket for the old motor

removed and the cross support has been milled down so it is even with

the fore and aft support.

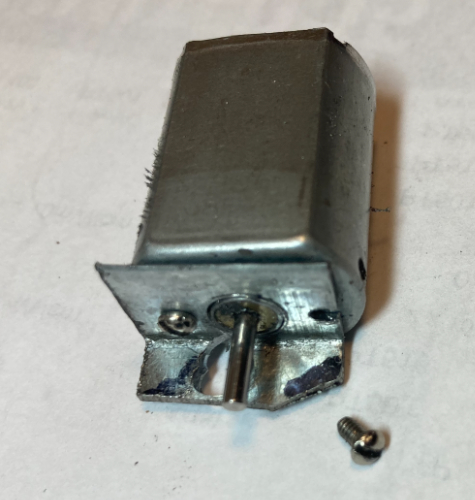

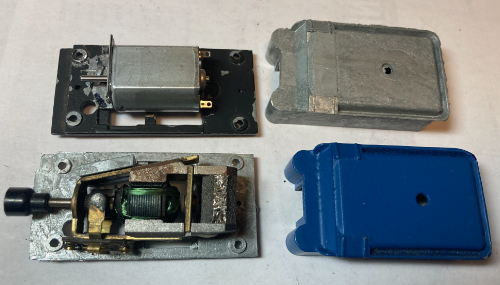

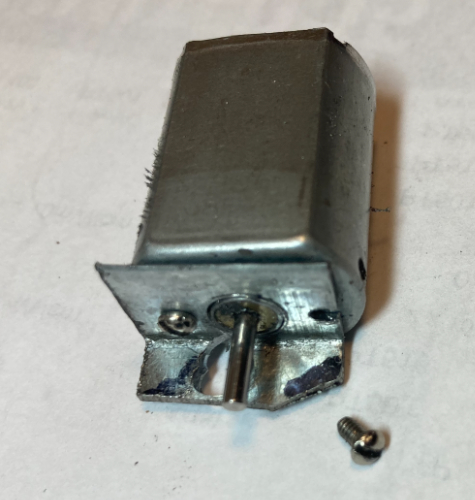

The PC-130 motors can be mounted with 2mm machine screws, though these screw will need to be shortened.

The mount is fabricated from a scrap piece of sheet metal. It

contains three holes on the upright side, two for the mounting screws

and a center hole for a drive shaft. The base contains a single

hole for a 6-32 mounting screw.

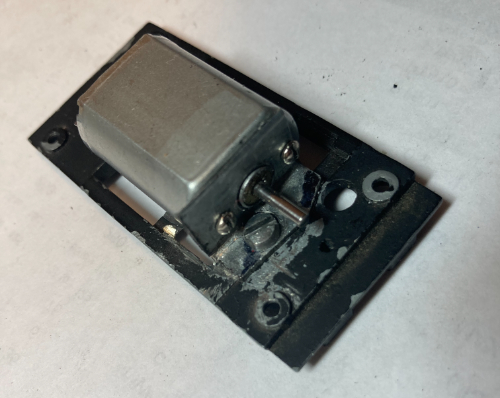

This image shows the motor partly attached to the mounting bracket and a shortened 2mm screw.

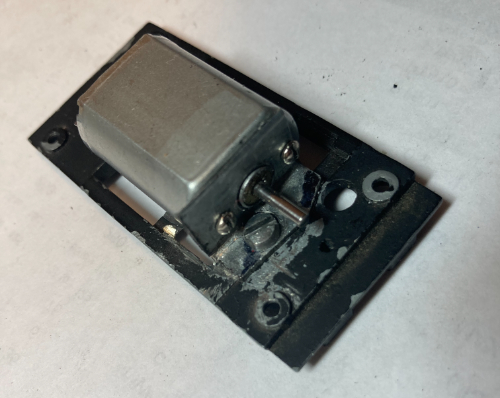

The bracket is attached to the frame with a 6-32 screw. The frame

must be carefully drilled and tapped. The position of the hole

must be carefully selected so that the screw does not interfere with the

truck or body of the tender.

The shorter PC-130 motor leaves room for a small DCC decoder.

Part 2 shows what it takes to connect a drive shaft from the tender to the engine.

Back to Mike's

Hobby Home Page