Model Railroad Automation Hardware

This page documents how I automated locomotive operation my City Point Terminal model railroad.

Go to this page to see how I automated switch operation.

Overview

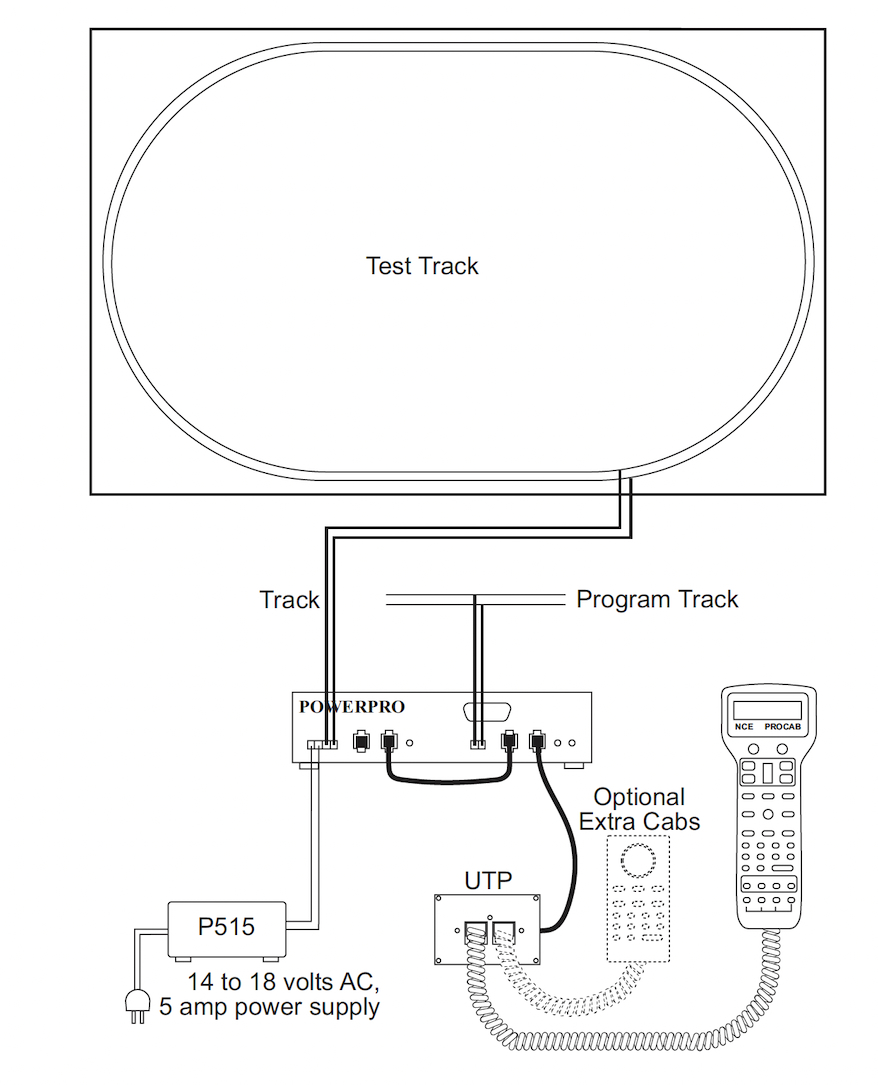

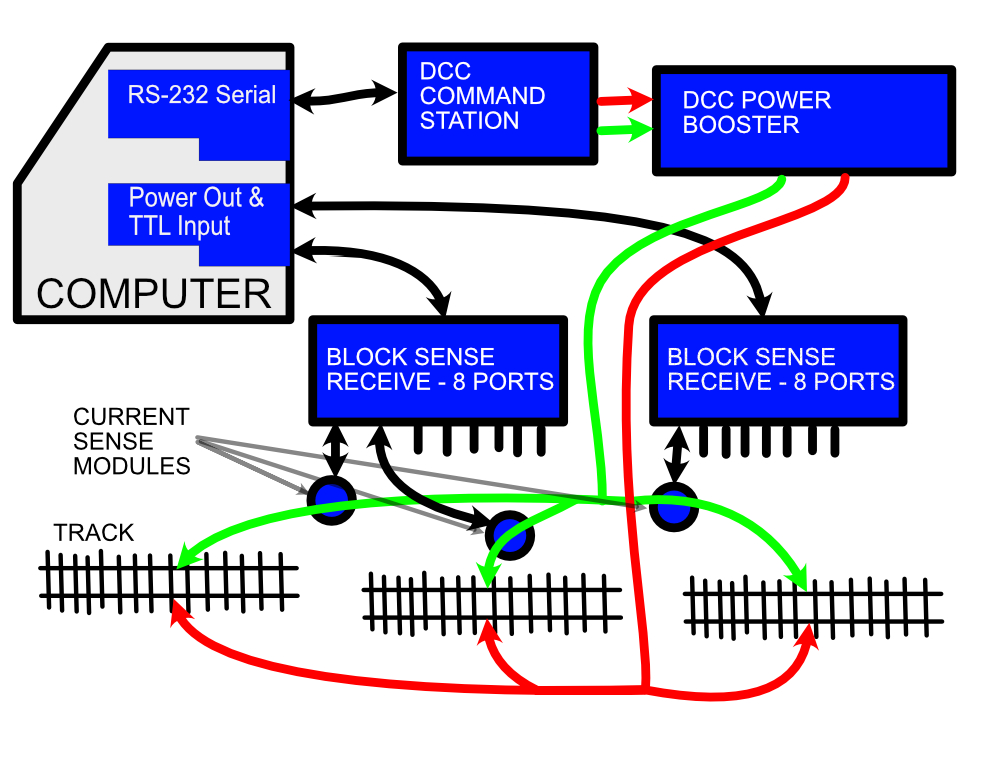

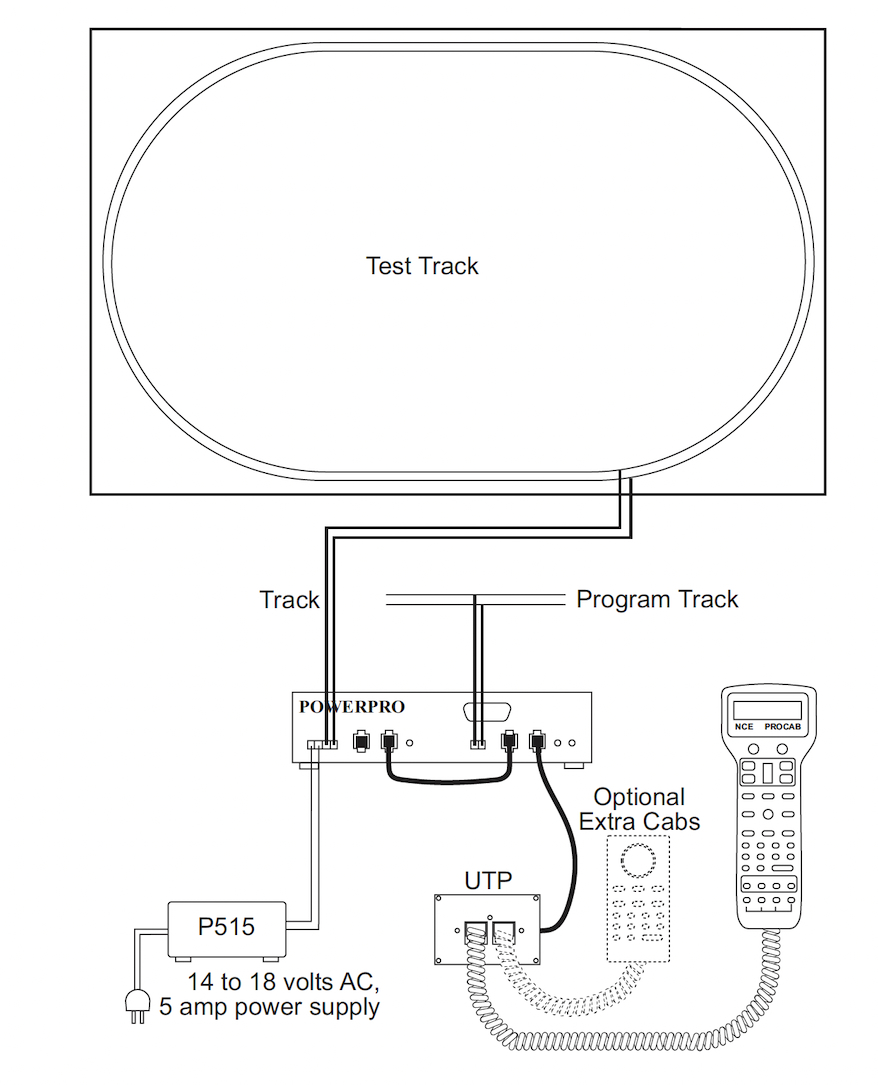

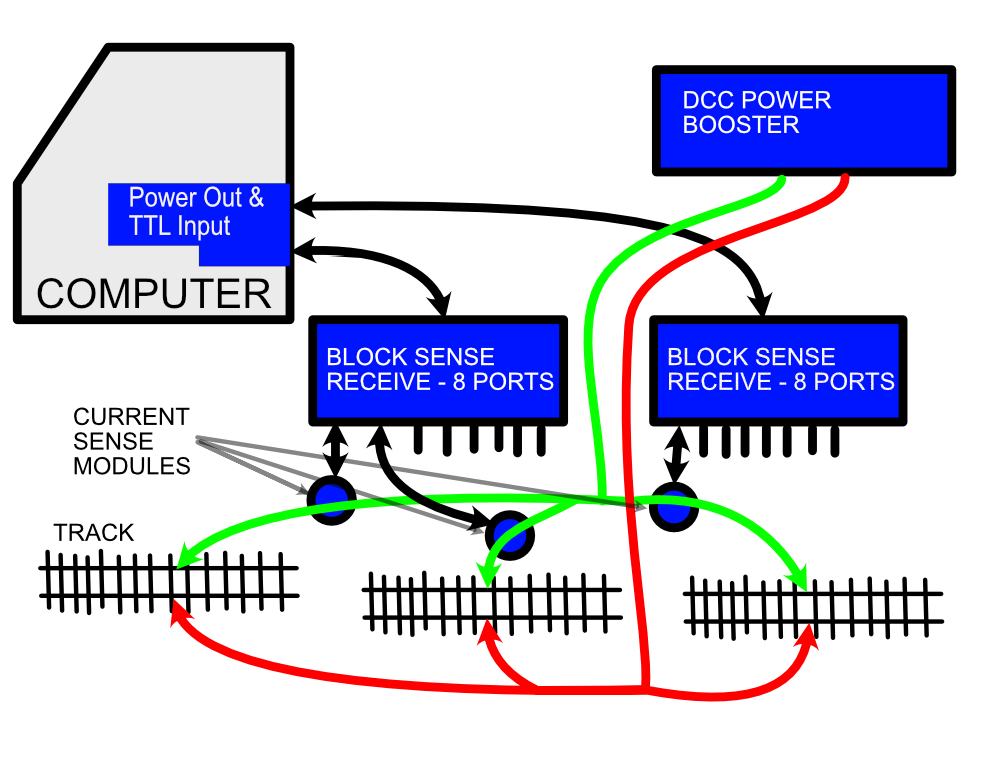

Basic Powerhouse Pro Block Diagram (from the manual)

The basic enabling technology for locomotive automation on my City Point

Terminal model railroad, is a NCE PowerHouse PRO DCC system. In a

DCC system, the control messages for the locomotive are generated by a

computer which is called the command station and the power that a

locomotive requires to turn it's motor comes from a special power

amplifier which is called a power booster. A combined power and

command signal is sent to the track from which

the locomotive both gets it's instructions and powers it's

motors. In a 5 Amp PowerHouse-PRO system, the booster and the

command station are combined into a single box, which is labelled

POWERPRO in the above diagram. Like many commercial DCC

systems, the command station uses a wired bus called a cab bus to

connect handheld throttles from which one or more users can send

messages to the command station, which in turn relays those commands to

one or more locomotives out on the track.

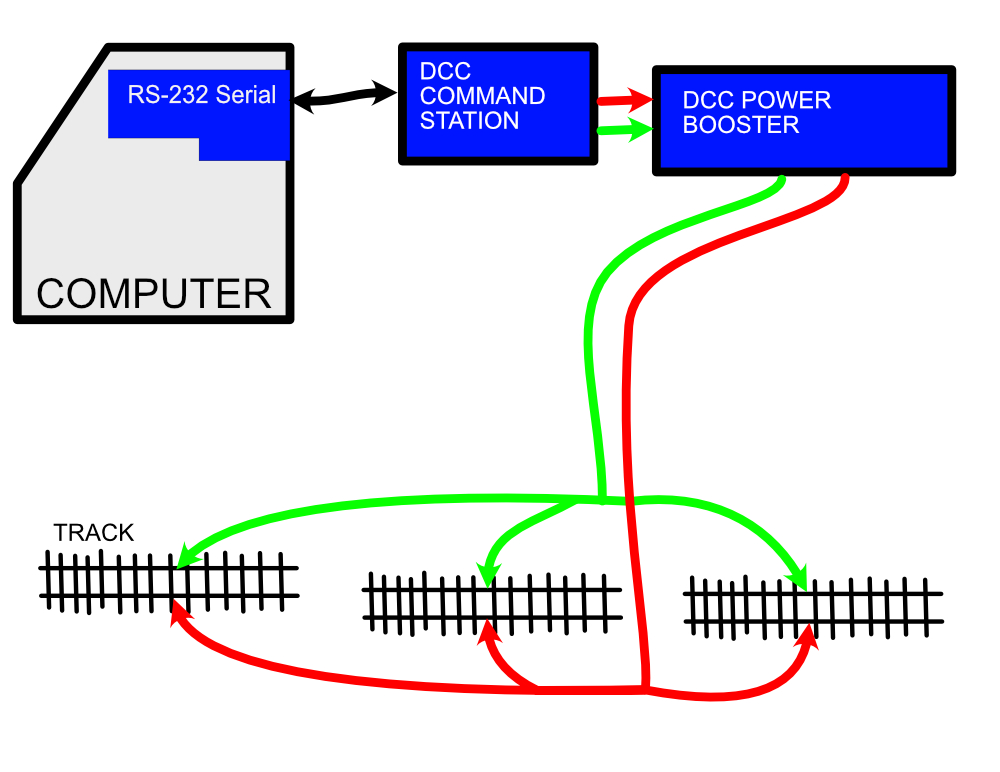

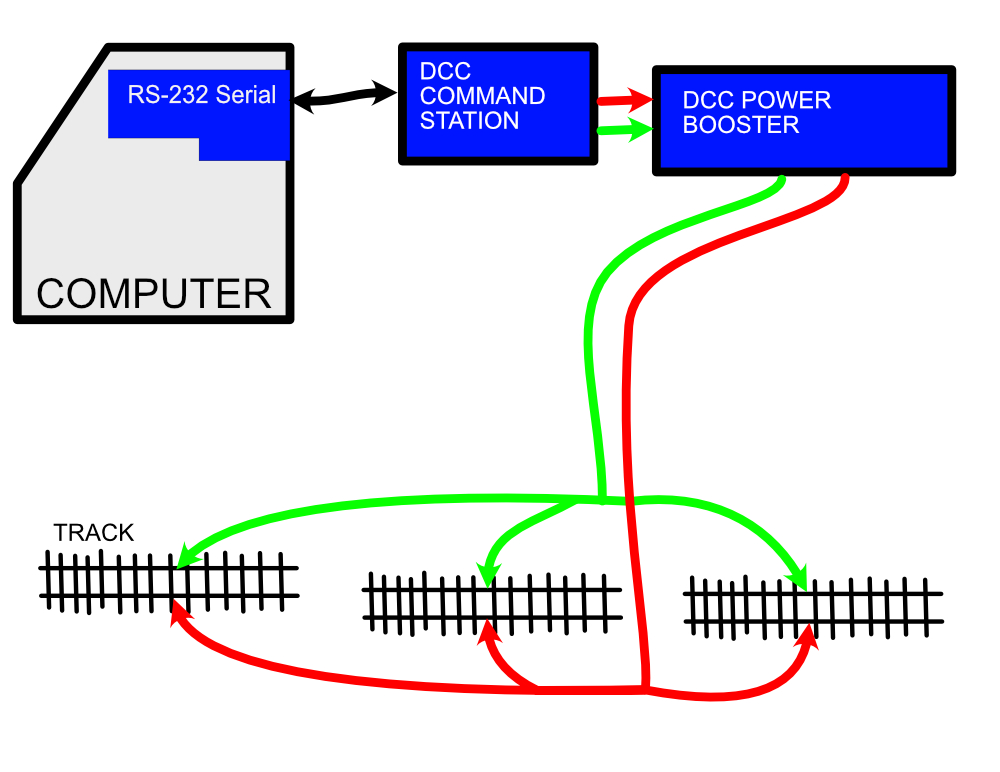

Basic RS-232 Communications

In addition to the cab bus, the NCE command station also supports input

from a RS-232 serial interface using a proprietary serial protocol that

is described in NCE documentation. This serial interface can

easily be connected to a computer which can be programmed to control

locomotives by sending messages to the DCC command station.

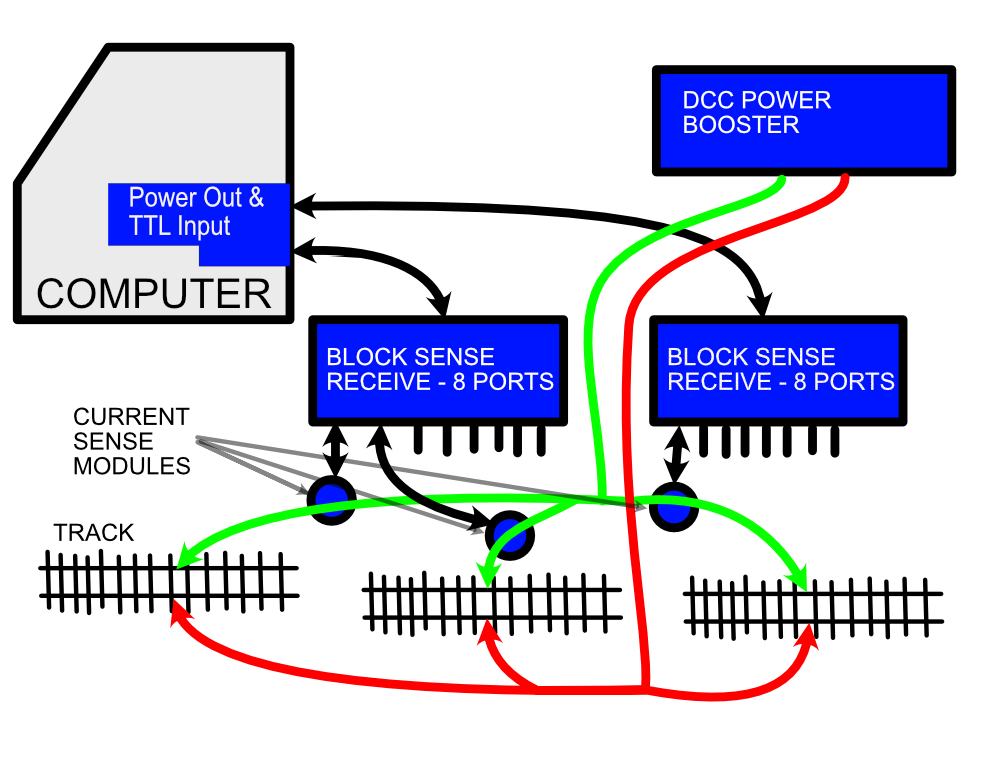

Basic Block Sensing With Three Blocks

In addition to being able to control locomotives, an automation system

needs to sense when a locomotive reaches a location on the layout, so it

can take action. For example, if the desire is to have a

locomotive stop when it reaches the end of the line or a station, the

automation system must be able to sense when the locomotive reaches that

point. The computer that is acting as the automation controller

will need to have sensor inputs in order to read the state of any

implemented sensors. There are many kinds of sensors that can be

used, each with it's own advantages and disadvantages.

Infrared detectors can sense when a train blocks a beam of infrared

light. This can be useful when it is important to have a sensor at

a very specific location. The disadvantage is that infrared

detectors must be mounted on the top of the layout where it can actually

sense changes in light due to a passing train.

Block sensors can detect when a a locomotive or specially equipped car

reaches a specific section of track. Block detection is usually

done by sensing when current is drawn from the DCC power booster by the

locomotive or a specially equipped car when it is in a specific section

of track. Track must be split into segments called blocks in order

to for this to be useful. Block sensors can only sense when a

locomotive or specially modified car is in a section of track.

Thus, the precision is limited to how long the section of track being

sensed is. One advantage is that the sensor can be be mounted out

of sight under the layout along with the DCC track wiring.

The design of my automation system is adaptable to a variety of types

sensor inputs, but at this point I have only implemented block sensor

input.

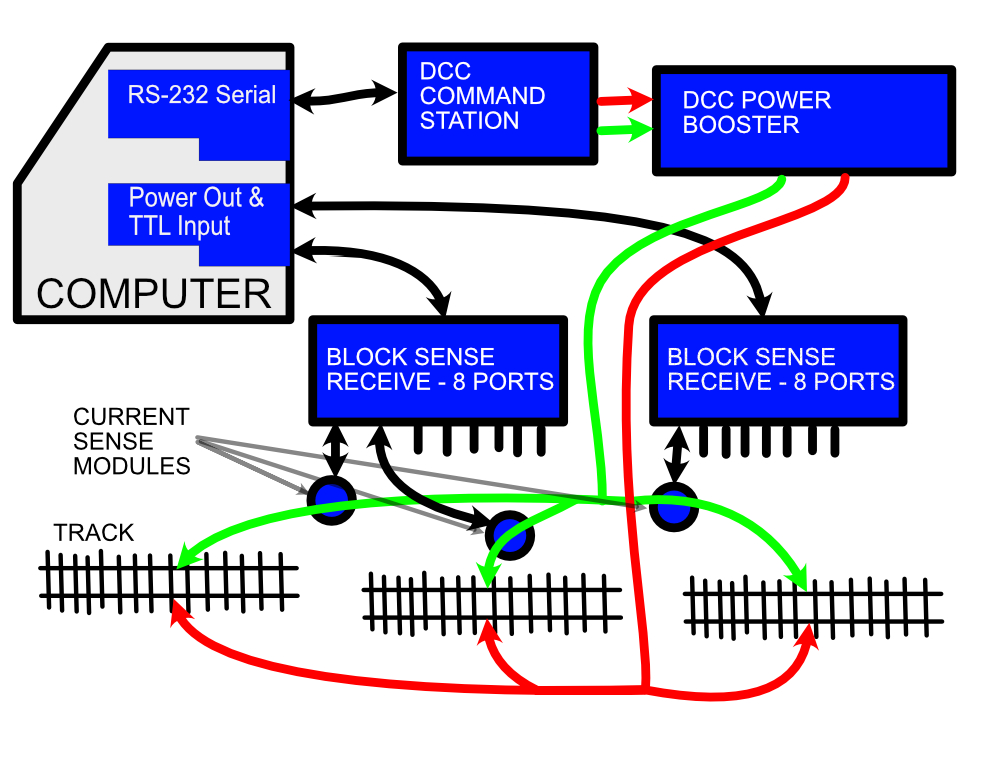

Basic Automation System With Three Sense Blocks

Combining the locomotive control system of the DCC command station with

an automation systems ability to sense locomotive location is all that

is necessary to implement a model railroad automation system. The

computer communicates with the DCC command station using RS-232 serial

signaling and gets status from the track through the sense system.

The rest of this document will delve into the details of the sense

system that I developed.

Automation Computer's Power and TTL Input Circuit

I choose to use an old Apple ][e computer as a host for my model

railroad automation system. One of the main reasons for this

choice was the ease in which I could add sensor inputs and control

outputs. Changing to a different host would involve replacing

the following interface with a circuit that is suitable for the system

to which you wish to port the application.

An Apple IIe has an integrated power supply, the BASIC programming

language, keyboard input and video output, and supports up to 7

expansion cards which are placed in card edge connector slots on the

motherboard. In my automation setup, one of the slots is used

for serial communications with the DCC command station. Another

slot is used for a floppy disk controller which makes saving and

altering the BASIC programs used to automate the layout rather

simple. This leaves 5 slots available for automation input and

output.

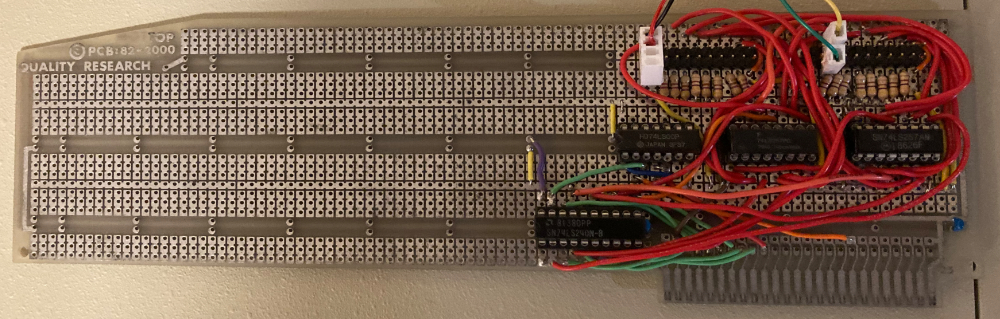

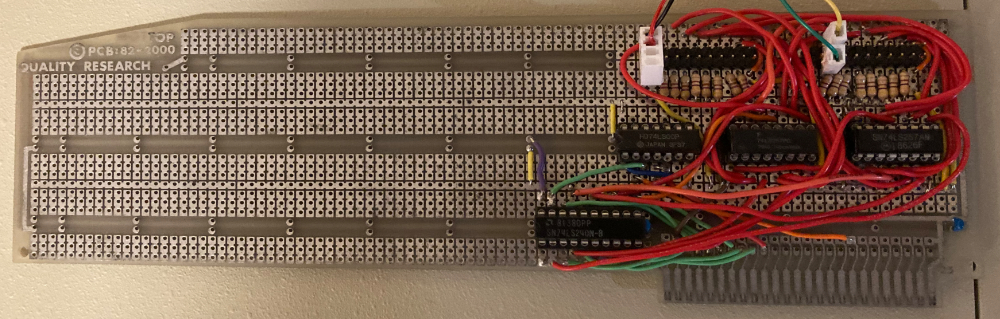

Prototype Sensor Input Board With a Single Test Input Connected

In order to get a basic automation system working, I decided to start by

implementing a card for reading block sense status. The card I

developed provides power and can gather status for up to 16 block

sensors. The input to the card comes through two 20 pin ribbon

cables. Each ribbon cable supports the power output, ground and

signal input for up to 8 sensors. A passive distribution

board to be described in the next section, is used to combine the

signals coming from the individual sensors to each incoming ribbon cable.

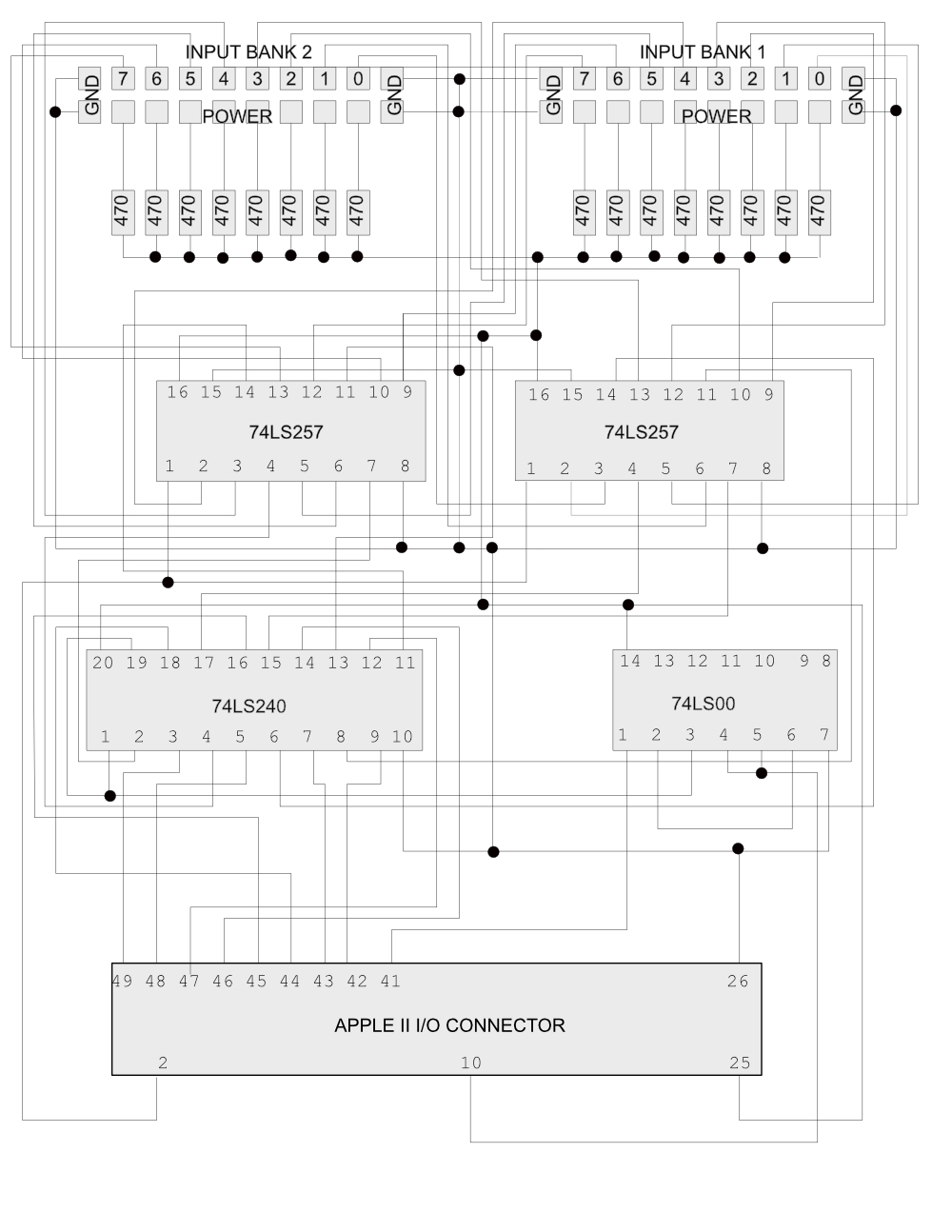

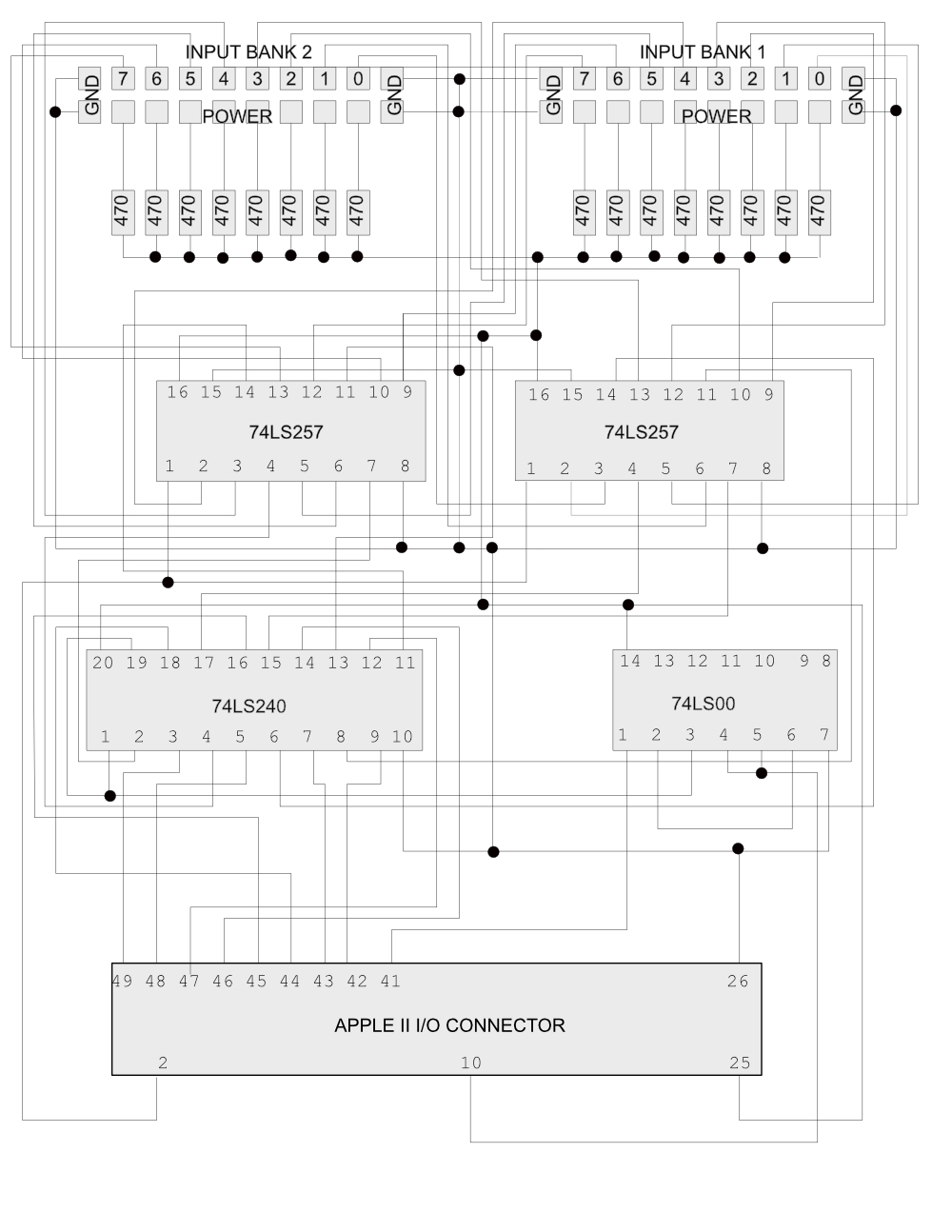

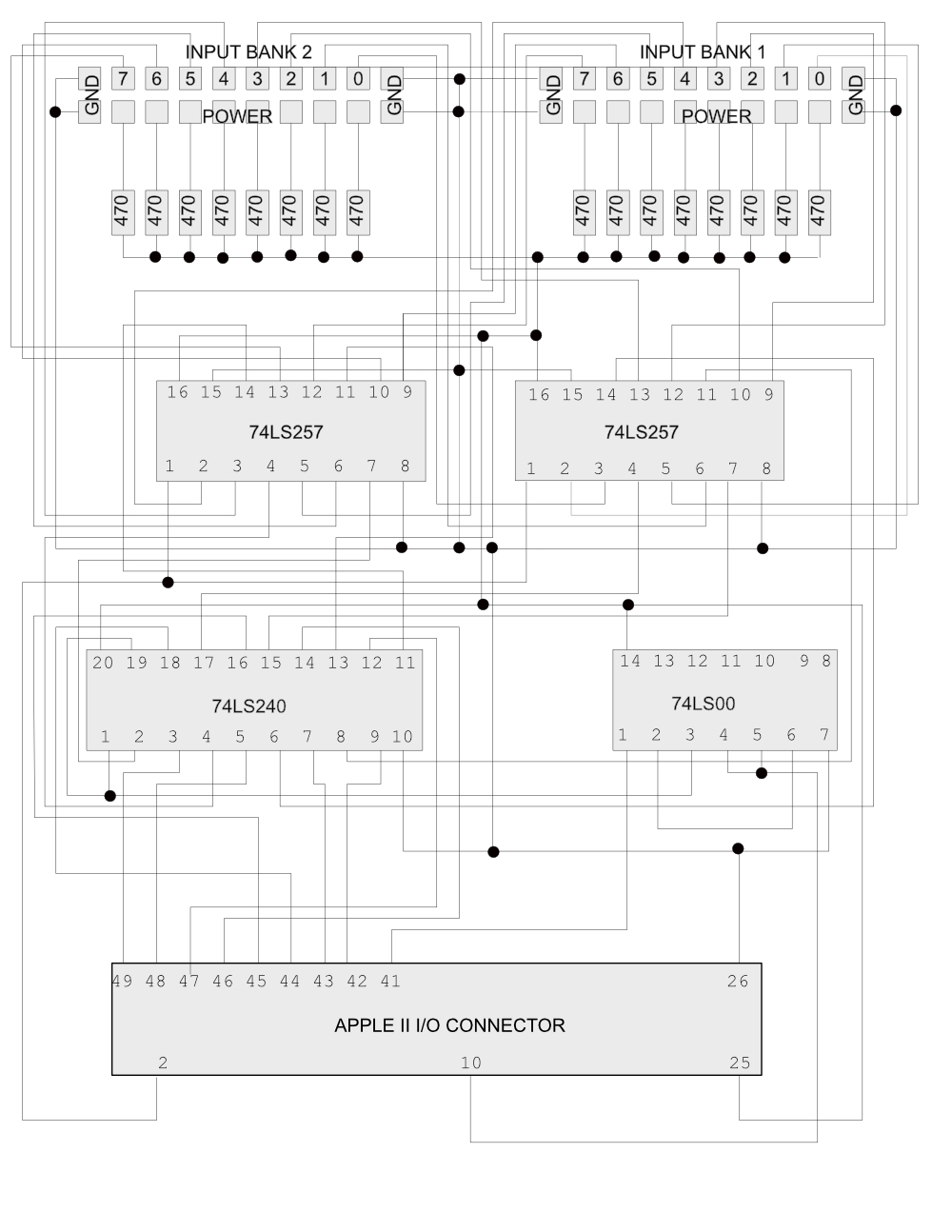

Sensor Input Board Schematic

The 74LS257 2:1 multiplexer chips steer either 8 bit set of sensor

inputs to the 74LS240 bus driver chip depending upon the state of Apple

bus address bit 0. The 74LS240 drives the Apple II data bus when

the processor reads from the slot in which this board is inserted in

to. That is the extent of the design for this card.

I could have added more banks of sensor inputs by switching to 4:1

multiplexers, but decided that it would be wise to limit the amount of

power consumption per card. In any case, there are plenty of

available slots, if I need to add more inputs in the future.

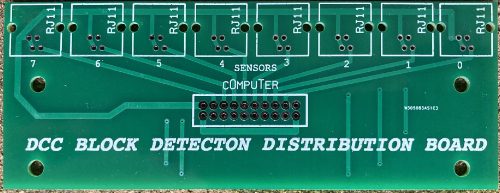

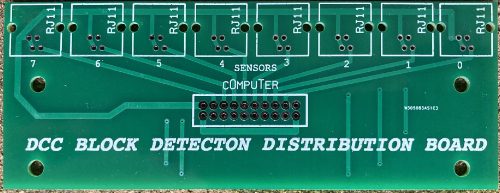

Sense Input Aggregation System

This Little Chassis Aggregates Sense Input

This box simplifies connection of sense inputs, sense power out and

ground. Each board takes the signals off two 20 pin ribbon cable s

and distributes to 16 RJ-11 jacks. All the grounds are tied

together and share the four ground wires on each ribbon cable.

Though only one board is currently installed, the pictured chassis can support

up to two aggregation boards for a total of 16 sense inputs.

Plain telephone cable is used to connect the signals from the

aggregation board to each sense circuit.

Unpopulated Aggregation Board

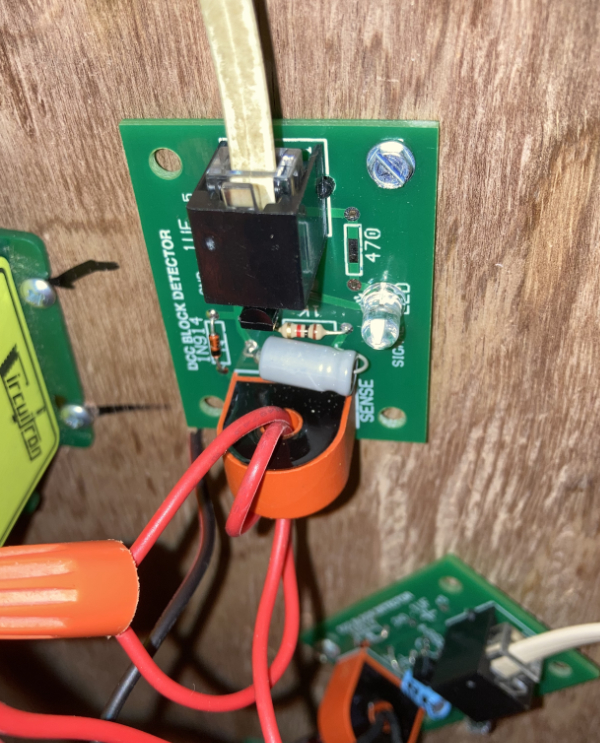

Block Current Sense Circuit

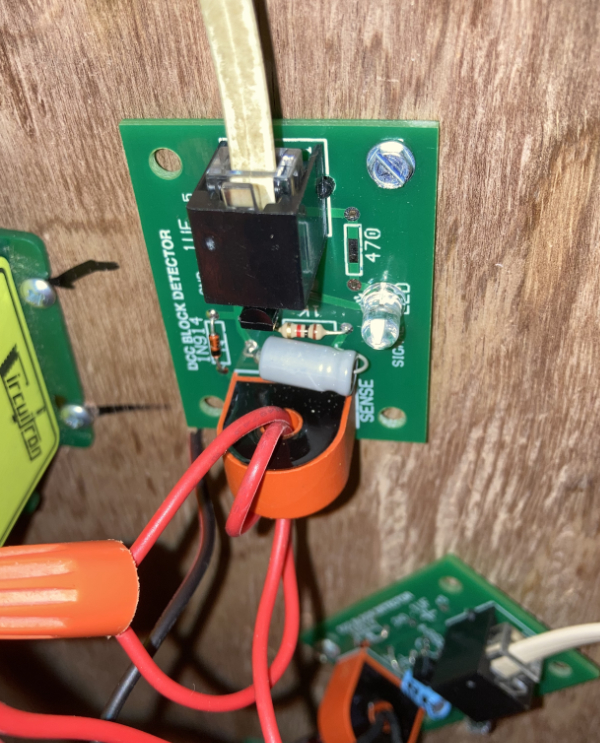

Installed Current Sense Detector

A key component of the automation system is a DCC current sense detector design that I found on the website: http://trainelectronics.com/DCC_Arduino/Current_Sense/index.htm

I first built a prototype of this circuit on a breadboard in order to

prove that it worked as described by Dave on his website.

In order to get it working reliably I found it best to use a much higher

value capacitor than Dave specified. After testing a number of

values I ended up settling on a 10uF capacitor.

I used a 1N914 diode and a 2n2904 transistor on my boards because that

is what I had in my stash, but I don't think that makes much

difference. I initially tested the circuit with a ferrite core

that I had laying around in a scrap box which worked fine. As I only had one of those I ended up buying the Gikfun

DIY 5A Range AC current transformer modules and made a batch of printed

circuit boards for the ferrite cores that came with the Gikfun kits.

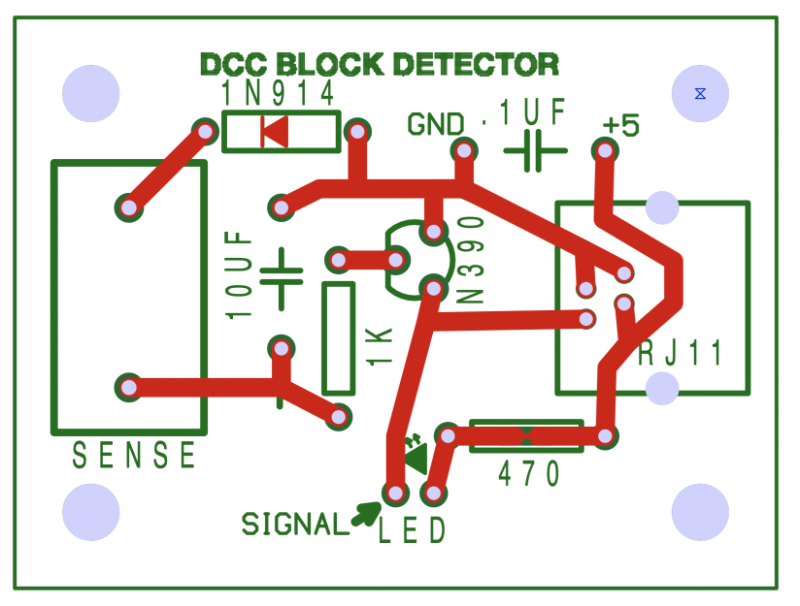

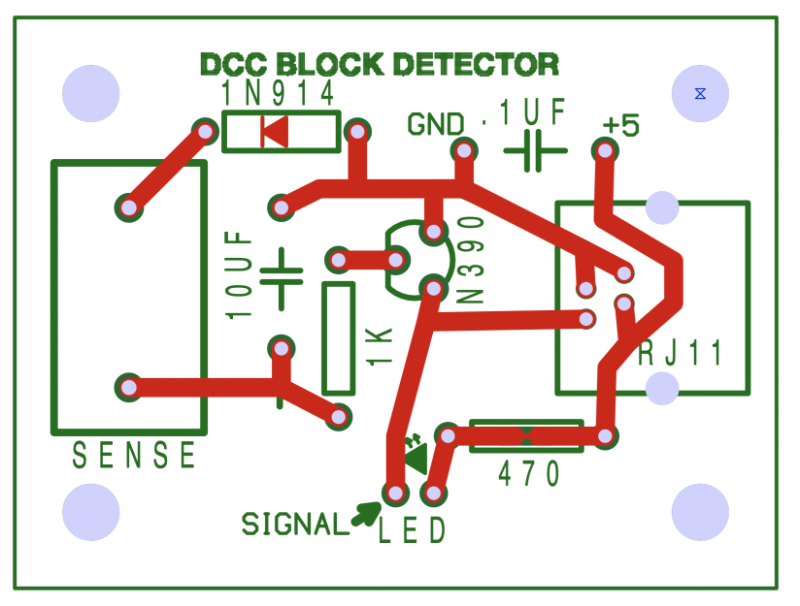

PCB layout - You Should Be Able to Easily Derive the Schematic From This Simple Layout

How This Current Sense Detector Works

One leg of the track power and the detector sense circuit are both wrapped

around the same ferrite core which makes the the core operate like a

transformer. When there is current flowing through the power wire

to the track, the transformer will transfer a little bit of the current

that is passing through to the current sense circuit.

The diode and capacitor act together as a rectifier and convert this

small copy of the DCC square wave signal into a DC level. When

enough current is passing through the ferrite core, the DC level will high enough that the

transistor will amplify it to the point that the TTL input on the host

computer interface board will recognize the signal as a high

input. This current flow also goes through the LED which

will light up. When little or no current is passing through the

ferrite core, the transistor will remain switched off. The TTL

input on the host computer interface board will read a low input from

the detector and the LED will have little to no current

flowing through it and will not be illuminated.

Connection to the aggregation box is via normal telephone cable with

RJ-11 connectors. Note that I designed my printed circuit boards

so the that the telephone connectors are oriented the same way on each

end of the cable which is different than some telephone

extension cables that I have purchased. I had to reverse the

orientation of the connectors on one end of those particular cables.

I made two other changes to Dave's design. I moved the 470 ohm

resister to the interface board on the Apple II computer. Just in

case I need to do things differently in the future, I designed the

circuit board with an option for a locally mounted resister. On my

layout, the resister location on the printed circuit board will be

left empty. I also put a spot for a power supply decoupling .1 uF

capacitor on the current sense circuit boards, but I found that I didn't

need to add that part either, so this spot on the circuit board is also

empty.

I found the circuit is very sensitive to number of times that the track

power line is looped through the ferrite core. The sense circuit will have some effect on the track voltage when a

locomotive is operating and drawing current. The more wraps, the

more sensitive the circuit will be. More wraps will also increase

drop of the track voltage, so there is a bit a compromise involved in

setting these current detectors up. For now, I have configured my

current sense detectors with two loops and pretty low sensitivity.

Of the three locomotives I'm experimenting with at the moment, only a

Bachmann Spectrum 2-8-0 with sound installed will trigger the current

sense when not actually moving. This is because only the DCC

decoder will be drawing current when the motor is not being used and DCC

decoders are pretty low current devices. My

software is able deal with this because it knows when locomotives are in

a block and are not moving. The software can ignore the sense input during these periods.