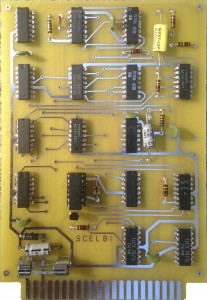

Each SCELBI board is protected from over voltage and over current with a fuse in series with a zener diode. For 5 volt supplies I use 1N5341 6.2 volt zener connected between the 5 volt supply and ground. For -9 volt supplies I use a 1N5349 12 volt zener connected between the -9 volt rail and ground. When the voltages are at normal values, the zeners do not conduct and remain inactive, not affecting the circuit. If the voltage exceeds 6.2 volts (on the 5 volt supply) or -12 volts (on the -9 volt supply), the zeners will start conducting, acting something like a short. This should prevent the voltage from rising any further above the switch on value of the zener, preventing damage to the circuitry. Also, if there is enough current, the fuse in series with the zener should blow, removing power altogether and saving the circuitry.

The main concern with this sort of circuit is that the zener cannot conduct infinite current for an infinite amount of time, before the zener itself acts like a fuse and blows. Once the zener blows, there is nothing to prevent the voltage from rising and destroying other components on the card. This is one reason that the SCELBI has different fuse ratings on different cards. The sooner that the fuse blows, the less likely that the zener will fail, first.

The 1N53XX diodes that I use on my reproduction SCELBI are not the same devices that were originally used. Though the 1N53XX devices have pretty good current handling capabilities, I was never quite positive that they would outlast the fuse in the case of an overvoltage event.

Last week, I decided to do a simple test in order to convince myself that these zener diodes would do the job in the case of a problem. The test I put together was quite simple. Simply connect a lab power supply to a fuse and a 1N5341 zener in series. Then crank up the voltage and amperage on the power supply and see if the fuse or the zener failed first. If the fuse went first, I knew the solution would be fine.

I started with a 1 AMP fuse. Adjusting the voltage to something greater than 6.2 volts and turning the amperage up to 1.5 AMPs resulted in a fuse that blew right away. Then I connected a 3 AMP fuse to see how the zener would fare under extended load. I didn`t leave the power supply on for too long, but the zener seemed to survive short tests without a problem. Finally, I turned the power up to 5 AMPs to see what would happen. After a few 10 second tests neither the zener nor the 3 AMP fuse blew. Since I didn`t really want to destroy the zener, I called the test a success.

The 1 AMP or smaller fuses used in the SCELBI would certainly blow before the zeners that I am using. As long as you use the correct fast blow fuses, I am quite comfortable recommending the 1N53XX series zener diodes for over voltage protection on the SCELBI cards.